Key points of quality control in plastic mold manufacturing

To ensure the quality of molds, quality control in plastic mold processing and manufacturing is a key link in mold manufacturing quality. Specifically, we can start from the following aspects:

(1) Effectively manage product data, process data, and drawing documents: effectively manage product data, process data, and drawing documents to ensure the comprehensiveness of files and the consistency of drawing versions; Enable effective sharing and query utilization of drawings. A complete file management computer database can be established to organize and utilize the design drawings, scattered information, and previously scattered and isolated information accumulated by the design department, in order to prevent problems caused by design drawings, 2D and 3D confusion, original, design changes, and maintenance versions confusion, inconsistency between 3D models and 2D drawing data, and non-standard and chaotic 2D drawing designs that are difficult to detect and correct in a timely manner, Causing modifications, rework, or even invalidation of the mold, increasing the manufacturing cost of the mold, prolonging the mold manufacturing production cycle, and affecting the delivery time.

(2) The design and manufacturing costs of each set of molds must be timely summarized: by effectively controlling the issuance of work vouchers in the workshop, the scrapping of cutting tools must be effectively managed; Through accurate mold structure design, efficient mold component processing, and accurate component inspection, the additional costs caused by mold design changes and maintenance will be effectively reduced, thereby obtaining the actual cost of each set of molds and effectively controlling mold quality.

(3) Maintain the consistency and completeness of mold drawings, processing techniques, and physical data: By effective, meticulous, and rigorous testing methods, ensure the consistency and completeness of mold drawings, processing techniques, and physical data.

(4) Overall planning: Organizes and integrates information such as planning, design, processing technology, workshop production status, and human resources to effectively coordinate planning and production, ensuring mold quality and delivering on schedule.

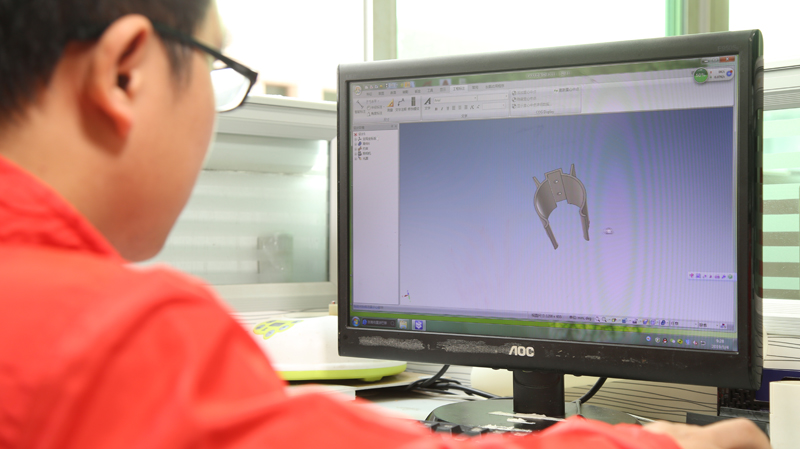

(5) Develop a complete and practical mold production management system: Develop a complete mold production management system to achieve a computer information management system for product data management, process data management, plan management, and schedule management in the mold production management process, including mold production plan formulation, mold design, process formulation, workshop task allocation and product inspection, warehouse management, etc, Enable comprehensive tracking and management of mold manufacturing and related auxiliary information from planning to completion and delivery.

(6) Establish a quality inspection department, strictly regulate testing methods, eliminate the mentality of "similar" luck, and ensure the accuracy of mold processing of various parts. Effectively control the quality of molds, and effectively relate quality to individuals based on previous and subsequent process records. It can enhance the design and operator's sense of responsibility.

(7) Based on the situation of our company and customers, develop mold design standards and mold design operation instructions that are suitable for our company and customers; Mold manufacturing standards, mold manufacturing operation instructions, standardized mold design and mold manufacturing; To prevent the old mold making thinking from creating molds that do not meet customer requirements due to personal habits.

With the gradual saturation of the market, the market demand is decreasing, and the personalized requirements for products are becoming higher and higher. In the past, plastic mold factories have won at a low price based on quantity

-

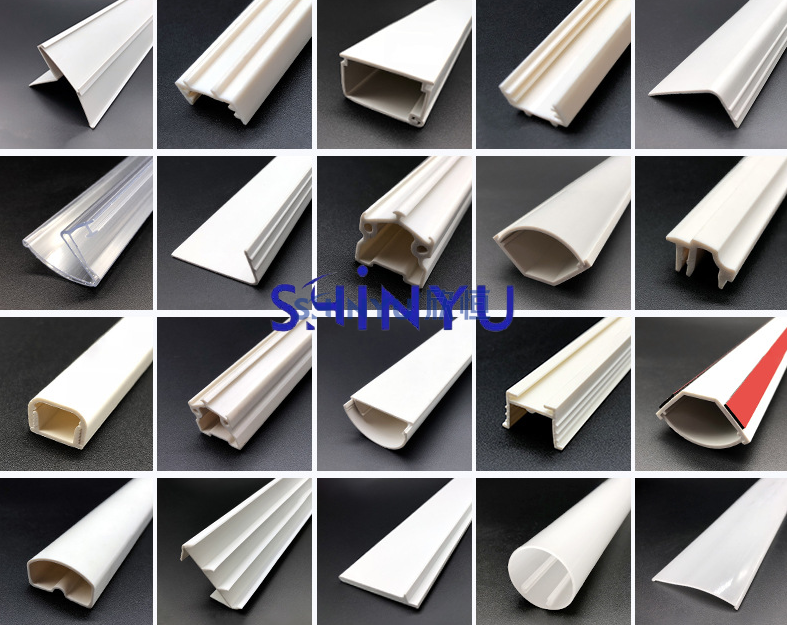

Characteristics of PVC plastic profile extrusion moldingJun,01,2023

Characteristics of PVC plastic profile extrusion moldingJun,01,2023 -

Prerequisites for customized Plastic ExtrusionsNov,01,2023

Prerequisites for customized Plastic ExtrusionsNov,01,2023 -

Key points of quality control in plastic mold manufacturingJun,01,2023

Key points of quality control in plastic mold manufacturingJun,01,2023 -

What are the aspects of understanding the production strength of injection molding manufacturers?Jun,01,2023

What are the aspects of understanding the production strength of injection molding manufacturers?Jun,01,2023

Links

Links