Prerequisites for customized Plastic Extrusions

Prerequisites for customized Plastic Extrusions

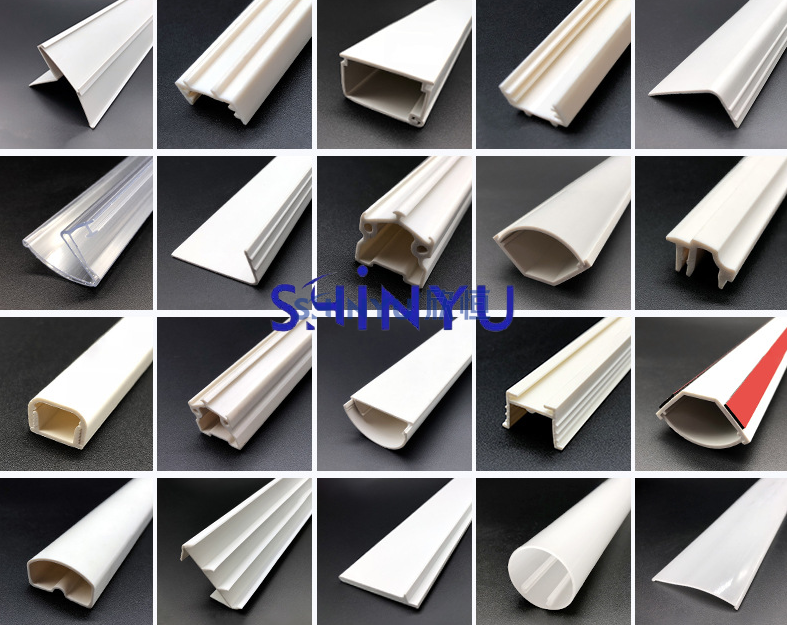

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Plastic extrusions are an integral part of many industries, from construction to packaging to automotive manufacturing. These extruded profiles are used for a wide range of applications, such as sealing, edging, framing, and molding which including pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

While standard extrusions may suffice for some projects, custom plastic extrusions are often necessary for unique designs and specific requirements.

We can customize the required plastic extrusion parts for customers according to the needs of specific projects. The customization scope can cover changes in product size, shape, color, material, and other aspects. Customized requirements can meet the unique and specific needs of different customers for products, and manufacturers can optimize product performance and functionality through continuous communication with customers, while reducing unnecessary costs. Create more market attractive final products while saving costs for customers.

The engineering and production departments are important departments for customizing plastic extrusion products. From communicating customer requirements with business, drawing design, R&D, and mold development to production, a team with professional technology and experience is required to develop products that meet customer satisfaction

Material Selection

Material selection is also an important part of product development. There are various types of plastic materials, such as ABS, PE, PP, pet, PVC, HDPE, etc. All belong to plastic materials. Therefore, it is necessary to have a professional understanding of the materials to choose what kind of materials to use and what expected results to be achieved. Our company has professionals proficient in the plastic industry, who will provide you with advice based on your design blueprint and the strength, durability, chemical and physical properties of each material to ensure that the final product meets the needs of customers.

Shinyu is an established production enterprise specializing in the plastic industry. From material selection, mold manufacturing, product development, to production and sales, we have a professional technical team to customize the plastic extrusion products you need. Experienced technical personnel provide you with various customized services, such as punching, riveting, drilling, alignment, assembly, deburring, cutting, and slotting.

We are committed to delivering high-quality and cost-effective parts on time every time. We sincerely hope we can have an opportunity to establish long-term business relationship with your company. As a factory, we would like to give you a best support.

-

Characteristics of PVC plastic profile extrusion moldingJun,01,2023

Characteristics of PVC plastic profile extrusion moldingJun,01,2023 -

Prerequisites for customized Plastic ExtrusionsNov,01,2023

Prerequisites for customized Plastic ExtrusionsNov,01,2023 -

Key points of quality control in plastic mold manufacturingJun,01,2023

Key points of quality control in plastic mold manufacturingJun,01,2023 -

What are the aspects of understanding the production strength of injection molding manufacturers?Jun,01,2023

What are the aspects of understanding the production strength of injection molding manufacturers?Jun,01,2023

Links

Links