Trunking construction: Safe and Efficient Trunking Installation Process

Title: Trunking Construction: Safe and Efficient Trunking Installation Process

1、 Introduction

Trunking construction is an indispensable part of modern architecture, which not only provides convenient wiring methods, but also ensures the safety and stability of the line. In this article, we will delve into the importance of trunking construction and share a safe and efficient trunking installation process.

2、 Type and selection of trunking

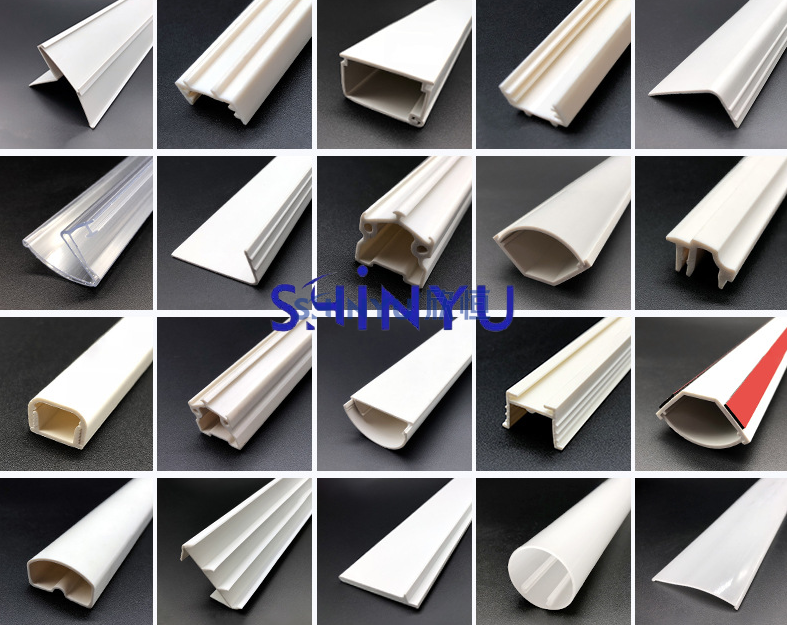

There are various types of wire ducts, which can be divided into metal ducts, plastic ducts, etc. according to their materials; According to the usage environment, it can be divided into indoor slots, outdoor slots, etc. When selecting the trunking, factors such as its load-bearing capacity, waterproof performance, and service life should be considered. Generally speaking, indoor metal grooves are a common choice and are suitable for most environments.

3、 Installation process of wire duct

1. Preparatory work: Firstly, determine the installation position and quantity of the trunking according to the design drawings. Then, conduct technical disclosure to the construction personnel to ensure that everyone understands the installation requirements.

2. Cutting the wire slot: According to actual needs, use professional cutting tools to cut the wire slot and ensure that the slot is flat.

3. Fixed trunking: Use expansion bolts, steel nails, and other tools to fix the trunking on the wall or ground to ensure stability.

4. Wiring: According to design requirements, place the wiring in the trunking and ensure that the wiring is neat and aesthetically pleasing.

5. Sealing the gap: cement or foam filler shall be used to seal the slot gap to prevent foreign matters from entering.

6. Test the circuit: After installation, conduct a circuit test to ensure that the circuit is unobstructed.

7. Cleaning the site: Clean the construction site to ensure cleanliness.

4、 Safety precautions

1. Wearing a safety helmet: Safety helmets must be worn at construction sites, especially when working at heights.

2. Wear anti-skid shoes: When working on wet or rough ground, anti-skid shoes should be worn to prevent falling.

3. Comply with electricity regulations: When installing and using electrical equipment, it is necessary to comply with electricity regulations to ensure safety.

4. Avoid scratches from sharp objects: When cutting wire grooves, professional tools should be used to avoid hand injuries.

5. Comply with safety operating procedures: During the installation process, follow the instructions to avoid accidents.

-

Characteristics of PVC plastic profile extrusion moldingJun,01,2023

Characteristics of PVC plastic profile extrusion moldingJun,01,2023 -

Trunking construction: Safe and Efficient Trunking Installation ProcessNov,15,2023

Trunking construction: Safe and Efficient Trunking Installation ProcessNov,15,2023 -

Prerequisites for customized Plastic ExtrusionsNov,01,2023

Prerequisites for customized Plastic ExtrusionsNov,01,2023 -

Work together to prevent and fight against epidemic diseases and protect production in an all-round wayNov,16,2022

Work together to prevent and fight against epidemic diseases and protect production in an all-round wayNov,16,2022 -

To organize fire safety drill training activities for all employeesSep,06,2021

To organize fire safety drill training activities for all employeesSep,06,2021

Links

Links